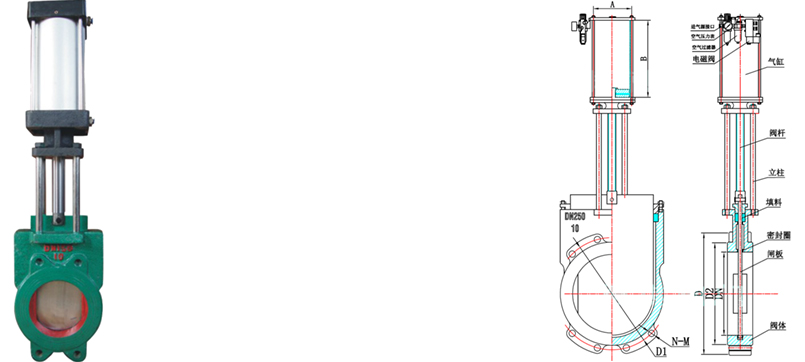

气动浆液阀安装尺寸以及外形图

发布时间:2016-05-30 11:37 已被浏览 次

产品概述

产品概述

气动浆液阀配用电磁阀、行程开关、过滤器等附件,以压缩空气为介质,将其能量转换成机械能,实现直线运动,可以完成开、关两位置的动作控制和信号输出,也可以完成连续动作的自动控制。

本阀门适用于糖浆、纸浆、泥浆、污水、煤浆等介质管路上,作启闭调节和节流使用,适用于水平安装,亦可倾斜安装。

1、采用对夹一体式结构,体积小,重量轻;

2、完全敞开的通道,可以防止介质在阀内的沉积;

3、采用可更换式密封结构,一改普通浆液阀与刀型闸阀维修难的问题。

技术参数范围

技术参数范围

公称压力:0.6MPa,1.0MPa,1.6MPa

公称通径:DN50-DN1000

适用温度:-10~+200℃

连接法兰:GB/T9113、JB/T79

主体材料:HT250,WCB,CF8

密封型式:软密封

泄 漏 量:A级(零泄漏)

配套附件:安装法兰

气动控制功能说明:

气动控制功能说明:

1、采用双电控三位五通电磁阀控制气动刀型闸阀气缸,采用三位开关,可控制闸阀在上限位、下限位及任意位置停留。

2、在上限位、下限位置停留时,上限位及下限位置的限位开关,发出一组常开或常闭的独立信号触点。可作为状态指示用。

3、浆液阀在上限位下限位置停留时,上限位及下限位置的限位开关,自动切断电磁阀相应控制线圈的电源。这样闸阀在上限位及下限位置长期停留时,电磁阀的电控线圈不通电,可避免电磁线圈发热提高电磁阀使用寿命,大大地提高了可靠性。

4、浆液阀在上限位及下限位置长期停留时;气源被切断不耗气,但锁定阀门气缸的气压仍保持在气缸中,能保证可靠停位。

5、在气缸开关过程中,切断控制电源,则气缸进出气也同时被切断,锁定阀门气缸的气压仍保持在气缸中,如气缸活塞、电磁阀及接头无泄漏,则闸阀可在任意位置长期停留。

气动执行器可选附件:

气动执行器可选附件:

1、单或双控电磁阀(有24V、220V等电压供选择,必要时可选取防爆电磁阀)。

2、接近开关。

3、气源处理三联件(包括减压阀、过滤器、油雾器)。

4、电/气动阀门定位器(调节型用)。

Product introduction

Product introduction

Pneumatic slurry valve solenoid valve, travel switch, filters and other accessories, with compressed air as medium, convert the energy into mechanical energy, to achieve linear motion, can complete both open and close position of the motion control and signal output, also can complete automatic control of continuous motion.

The valve is suitable for pipeline conveying such mediumsin cluding syrup,paper pulp,sludge,sewage,coal slurry,etc.for controlling switching on/off and throttling.It allows horizontal mounting as well as inclined mounting.

1、Adopts the one-piece structure, small volume, light weight;

2、Completely open channel, can prevent the deposition of medium inside the valve;

3、Adopting replaceable type sealing structure, changes the ordinary type slurry valves and knife gate valve, the difficulty of maintenance。

Technical Parameter Range

Technical Parameter Range

Nominal pressure:0.6MPa,1.0MPa,1.6MPa

Nominal diameter:DN50-DN1000

Suitable temperature:-10~+200℃

Flange drilling:GB/T9113、JB/T79

Main materials:HT250,WCB,CF8

Seal type:Teflon soft seal

Accessories:Flange

Pneumatic control function:

Pneumatic control function:

1、Adopts double electric control three five-way solenoid valve control type pneumatic knife gate valve cylinder, adopt three switch, can control valve in the ceiling, floor and any place to stay。

2、Stay in the ceiling, floor, the upper limit and lower limit position limit switch, send out a set of normally open or normally closed contact independent signal, can be used as a status indication。

3、Slurry valves at a UCLA's position, the upper limit and lower limit position limit switch, automatic cut off the power of the corresponding control solenoid valve coil. This gate valve a long stay in the upper limit and lower limit, the electromagnetic valve of the electric coil not electricity, can avoid electromagnetic coil heat to improve the service life of the solenoid valve, reliability has been greatly increased。

4、Slurry valves when the upper limit and lower limit position long stay; Air supply is cut off gas consumption, but locking valve cylinder pressure remained in the cylinder, can guarantee the reliable parking。

5、In the process of the cylinder switch, cut off the control power, the cylinder in and out of gas at the same time also is cut off, lock the valve cylinder pressure remained in the cylinder, piston cylinder, solenoid valve and joint without leakage, the gate valve can be a long stay in any position。

Pneumatic actuators optional accessories:

Pneumatic actuators optional accessories:

1、Single or double control solenoid valves (24 v, 220 v voltage to choose from, such as selecting explosion-proof solenoid valve when necessary)。

2、Proximity switch。

3、Air source treatment sanlian pieces (including pressure reducing valve, filter, oil mist device)。

4、Electric/pneumatic valve positioner (external regulation)。

|

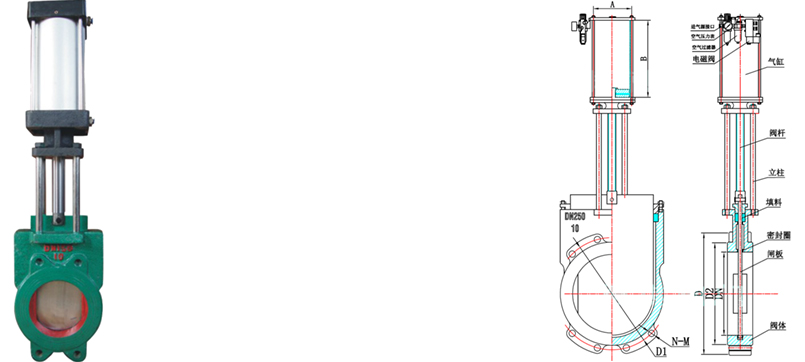

主要外形及连接尺寸Profile and connection dimension 主要外形及连接尺寸Profile and connection dimension |

单位Unit:mm 单位Unit:mm

|

|

PN |

DN |

L |

D |

D1 |

D2 |

H |

N-M |

A |

B |

PN |

DN |

L |

D |

D1 |

D2 |

H |

N-M |

A |

B |

|

0.6 |

50 |

40 |

125 |

100 |

90 |

335 |

4-16 |

63 |

50 |

1.0 |

50 |

40 |

125 |

100 |

99 |

335 |

4-16 |

63 |

50 |

|

65 |

40 |

145 |

120 |

100 |

363 |

4-16 |

80 |

65 |

65 |

40 |

145 |

120 |

120 |

363 |

4-16 |

80 |

65 |

|

80 |

50 |

160 |

135 |

125 |

395 |

4-16 |

80 |

80 |

80 |

50 |

160 |

135 |

135 |

395 |

4-16 |

80 |

80 |

|

100 |

50 |

180 |

155 |

145 |

465 |

4-16 |

100 |

100 |

100 |

50 |

180 |

155 |

155 |

465 |

4-16 |

100 |

100 |

|

125 |

50 |

210 |

185 |

175 |

530 |

4-16 |

125 |

125 |

125 |

50 |

210 |

185 |

185 |

530 |

4-16 |

125 |

125 |

|

150 |

60 |

240 |

210 |

200 |

630 |

4-20 |

160 |

150 |

150 |

60 |

240 |

210 |

210 |

630 |

4-20 |

160 |

150 |

|

200 |

60 |

295 |

265 |

255 |

750 |

4-20 |

160 |

200 |

200 |

60 |

295 |

265 |

265 |

750 |

4-20 |

160 |

200 |

|

250 |

70 |

350 |

320 |

310 |

900 |

8-20 |

160 |

250 |

250 |

70 |

350 |

320 |

310 |

900 |

8-20 |

160 |

250 |

|

300 |

70 |

400 |

368 |

362 |

1125 |

8-20 |

200 |

300 |

300 |

80 |

400 |

368 |

375 |

1125 |

8-20 |

200 |

300 |

|

350 |

80 |

460 |

429 |

412 |

1260 |

10-20 |

200 |

350 |

350 |

90 |

460 |

429 |

435 |

1260 |

10-20 |

200 |

350 |

|

400 |

80 |

515 |

482 |

462 |

1450 |

10-22 |

200 |

400 |

400 |

120 |

515 |

482 |

485 |

1450 |

10-22 |

200 |

400 |

|

450 |

90 |

565 |

532 |

518 |

1600 |

14-22 |

250 |

450 |

450 |

120 |

565 |

532 |

545 |

1600 |

14-22 |

250 |

450 |

|

500 |

100 |

620 |

585 |

568 |

1820 |

14-22 |

250 |

500 |

500 |

130 |

620 |

585 |

609 |

1820 |

14-22 |

250 |

500 |

|

600 |

100 |

725 |

685 |

670 |

2300 |

14-27 |

300 |

600 |

600 |

140 |

725 |

685 |

720 |

2300 |

14-27 |

300 |

600 |

|

700 |

100 |

940 |

800 |

775 |

2600 |

16-27 |

300 |

700 |

700 |

140 |

940 |

800 |

788 |

2600 |

16-27 |

300 |

700 |

|

800 |

120 |

950 |

905 |

880 |

3000 |

16-27 |

320 |

800 |

800 |

150 |

950 |

905 |

898 |

3000 |

16-27 |

320 |

800 |

|

900 |

120 |

1050 |

1005 |

980 |

3400 |

20-30 |

320 |

900 |

900 |

150 |

1050 |

1005 |

998 |

3400 |

20-30 |

320 |

900 |

【声明】: 以上文章或资料除注明为上海前泽阀门有限公司自创或编辑整理外,均为各方收集或网友推荐所得。其中摘录的内容以共享、研究为目的,不存在任何商业考虑。

目前网站上有些文章未注明作者或出处,甚至标注错误,此类情况出现并非不尊重作者及出处网站,而是因为有些资料来源的不规范。如果有了解作者或出处的原作者或网友,请告知,本网站将立即更正注明,并向作者道歉。

被摘录的对象如有任何异议,请与本站联系,联系邮箱:a59168@126.com,本站确认后将立即撤下。谢谢您的支持与理解!

产品概述

产品概述 技术参数范围

技术参数范围 气动控制功能说明:

气动控制功能说明: 气动执行器可选附件:

气动执行器可选附件: Product introduction

Product introduction Technical Parameter Range

Technical Parameter Range Pneumatic control function:

Pneumatic control function: Pneumatic actuators optional accessories:

Pneumatic actuators optional accessories:

主要外形及连接尺寸Profile and connection dimension

主要外形及连接尺寸Profile and connection dimension 单位Unit:mm

单位Unit:mm